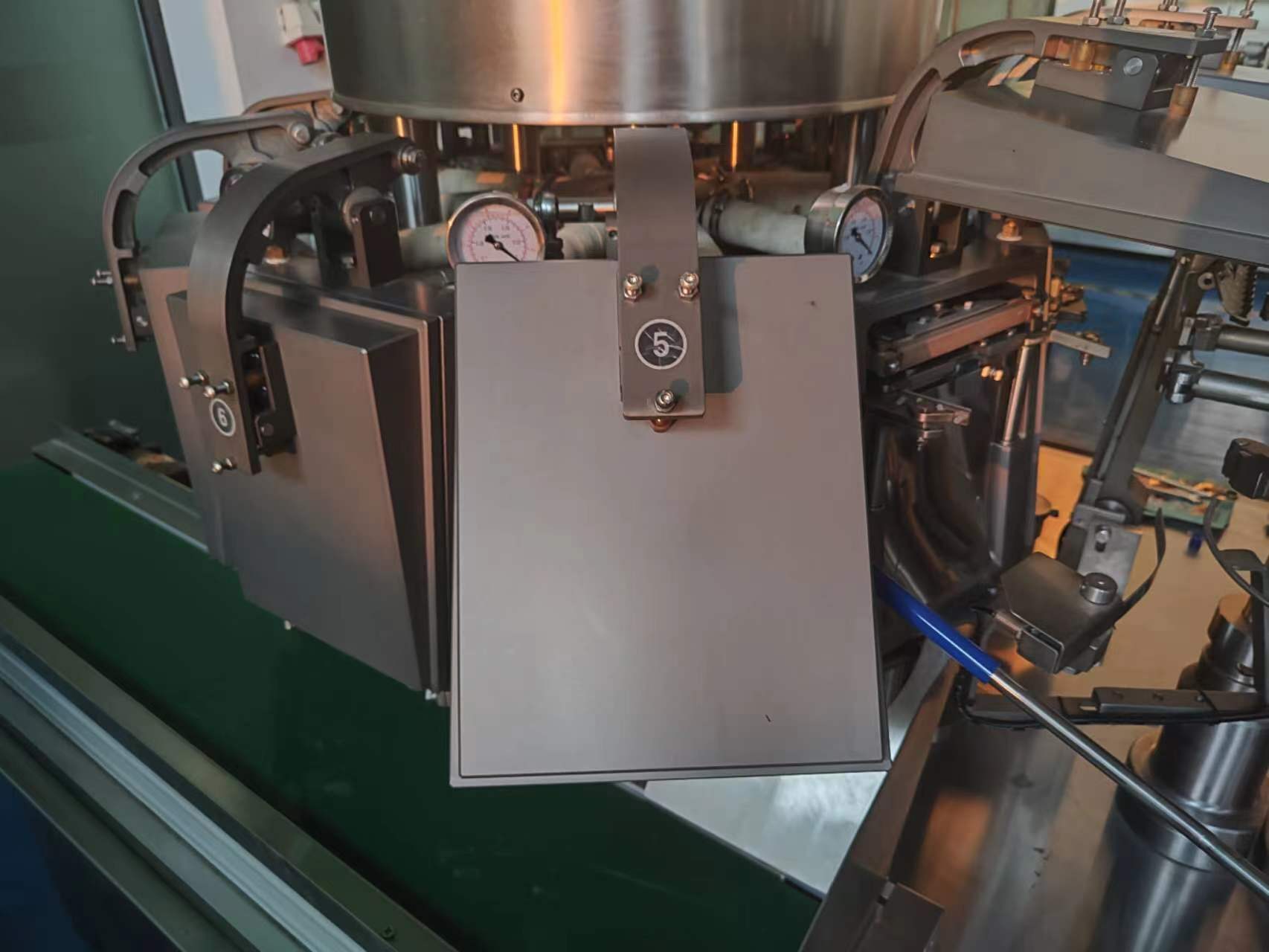

Rotary Pre made Pouch Pet Food Dog Food Packaging Machine

- FRONTECH

- CHINA

- 30 days

- 50 set/month

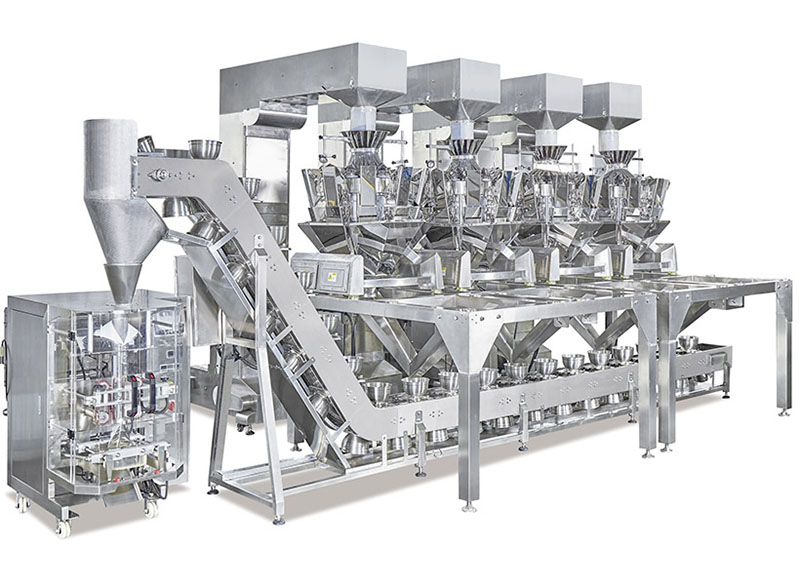

Rotary Packaging Machine capable of packing different kinds granule products like dog food, pet food, etc.

Application

Rotary pre made pouch packing machine capable of working with different kinds of dosing system, capable of packing different kinds of products like pet food, dog food, puffed food, patoto chips, coffee bean, crispy rice, jelly, candy, pistachios, vegetable salad, dumplings, glutinous rice balls, chocolate, apple slices, banana chips, frozen food, medicines etc.

Parameters

| tem | FT-R8200 | FT-R8250 | FT-R8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

Measurement accuracy | *≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

Features

With different kind of dosing system, capable of packing a wide range of products.

Capable of working with a range of pouches.

Easy to operate, With PLC controller, HMI system makes easy operation.

Easy to adjust bag size on the screen, then the machine will do the adjustment accordingly

High automation, automatic feeding, bag picking, filling, closing, sealing, date coding.

Perfect prevention system: when the bag is not opened or not opened completely, it will be non-filling and non-sealing, so the bags can be reused and the product is not wasted thus save the production cost.

The product contact parts are made of food grad SUS304 to ensure sanitation and safety.

High quality plastic bearings, no need to oil, no contamination.

Vacuum generator, low consumption, high efficiency, cleaness, and long useful life.

Sample bags